Producing braille begins with transcription. Transcriptionists use special software, such as Duxbury, to transcribe written/print words into braille code. Most books arrive at NBP in hard copy and are scanned into a digital file, although some do arrive digitally. Braille code looks similar to HTML and other computer coding, using different sequences for complex formatting of braille letters, words, paragraphs, and pages. Transcriptionists need to look at all the pages, fix contractions, number the pages, and format the words — center, bold, italic, etc — before the braille copy is reviewed by a proofreader.

After the transcriber has the braille copy made, the first draft is sent to our proofreaders, usually in an electronic braille file (brf). These .brf's are read on a braille note-taker/computer that has refreshable, electronic braille pins. While reading the braille file, proofreaders will also listen to someone reading the print text, to check that everything matches up exactly. Any needed corrections are marked by the proofreader and the copy is sent back to the transcriber.

Once everything is proofread and edited, it's ready to be embossed! An electronic file containing the braille code directs a Plate Embossing Device (PED) to put braille dots onto a zinc plate. The plate contains dots on both sides, referred to as interpoint braille. It takes about 35 seconds for a PED to emboss one side of the plate. These are then checked again by our amazing proofreaders to make sure everything has been embossed accurately and these plate become the braille template for that page, used to produce many copies!

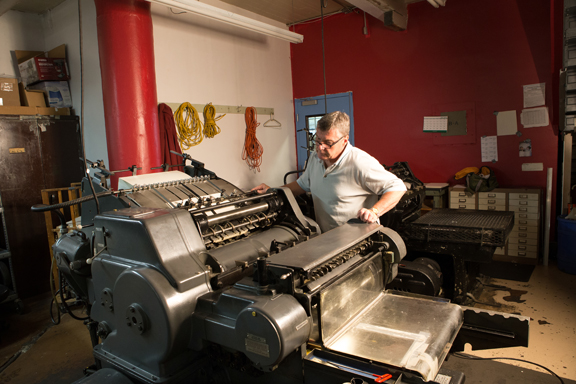

After the braille plate have been embossed and check for errors they head down to our presses for mass production. Right now, NBP has two different types of presses: 1. Modified Heidelberg printing presses that can print about 10-20,000 pages per hour, with the downside being that they do not collate, and so a lot of that will need to be done by hand; 2. Newer printers that use a giant roll of paper and collate all the pages, but print at a slower rate of 200-300 pages per hour. This process is called pressing because the zinc plate are literally pressed into the braille paper to produce the final product.

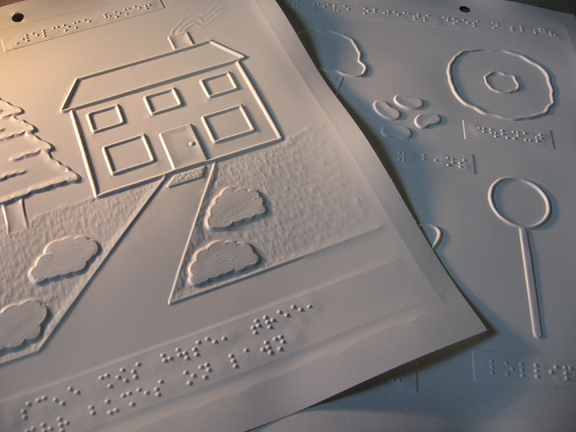

Some of NBP's projects, such as textbooks will contain tactile graphics, or images. These are made by using a plastic-like paper called thermoform paper. The thermoforming machine also uses a metal plate, this time with a tactile graphic, and the paper is laid over it. Heat, heats up the paper so that it will form to the mold, and a vacuum pulls them together to get an accurate image. This process is very hands on and always constantly monitored to make sure the images are crisp, clear, and not distorted; each page is done individually.

Because the Heidelberg presses only do one page at a time, many of our jobs need to be collated by hand. These pages are put on shelves and then laid out, in order, on long tables. Our production team goes through the piles, putting the pages in order. There is one final check by the proofreaders to make sure all the pages are in order and then they are bound or stitched together to produce the final product.

We enjoy showing the general public how we produce braille. To request a tour date, please call 617-425-2412, or email us.

Cost: There is a recommended donation of $25 for up to 5 people. Larger groups are charged $3.00 per person. Please send checks payable to National Braille Press, 88 St. Stephen Street, Boston, MA 02115 USA

Reservations Needed: Yes, reservations are required. We ask for at least two weeks' notice.

Days and Hours: By appointment only. Times avalible to book are Tuesdays and Thursdays at 10:30 am or 1:00 pm; we do not except drop-ins at any times.

Length of Time: 1 hour

Minimum Age: While there is no official minimum age, children should be at least 6 years old to appreciate the tour. We try to make the tour more interactive for children.

Address:

- National Braille Press

- 88 St. Stephen Street

- Boston, MA 02115

Telephone:

- Main Number: 617-266-6160

- 888-965-8965 (toll free)

- Bookstore: 800-548-7323 ext. 520 (toll free US only)

Fax:

- Main Fax: 617-437-0456

- Education Services Fax: 617-425-2462

- Email: contact@nbp.org

By Subway

Take the "E" train on the Green Line outbound to the Northeastern University stop on Huntington Ave. When you exit the train, turn right. Walk along Huntington until you reach a down-slope and an opening on the left. At that opening, cross over Huntington Ave and turn right. Walk about ten steps and cross over Opera Place (it will be right in front of you). Take a left on Opera Place, pass an alleyway on your right, and continue until you reach the end of the block. Turn right onto St. Stephen Street. Our building is halfway down the block on your right. You'll walk over two grates and the sidewalk slopes slightly to the left, just before you reach a set of stairs leading up to our front door.

By Car

Take the Massachusetts Ave. exit on 1-93 (Southeast Expwy.). Turn right on Massachusetts Ave. and go straight until you cross Huntington Ave. At Symphony Hall (on your left), turn left on St Stephen Street. National Braille Press is ahead on your left.

Parking

Metered parking is available along Saint Stephen Street. The nearest parking garage is the Westland Avenue Garage. When following the driving directions above, instead of turning left onto Saint Stephen Street, turn left onto Westland Avenue (it's the same turn - a 3-way corner; for Westland, bear right after you turn). The Westland Avenue Garage is about 50 yards on the right, above Whole Foods.

- Dear National Braille Press,

The staff gave us the most wonderful tour. It truly was not what I expected, I was looking for a mass production of machines and staff. The work that you do is incredible. I was humbled beyond words. I have been working in this field for four years and I am so appreciative of what you do for the blind. Please tell your staff, "THANK YOU AND WHAT A GREAT SERVICE THEY ARE DOING!"

- Sincerely,

- Ellen Dumont

- Qualters Middle School, Mansfield, MA

- Dear National Braille Press,

Thank you for teaching us about braille. We learned a lot! Making braille books is a wonderful idea, especially print and braille together. Wow, what a BIG DICTIONARY! It is amazing how many volumes Harry Potter books are. They would be very heavy to carry. We enjoyed learning how Steve gets around. His watch is neat. The machines are big and noisy. It is amazing that the computers can talk and read a printed page. It was fun stomping on the metal sheets of braille. We think the machines work much better. We hope they don't make too many mistakes.

We had a fun trip. Thank you for your patience. Thank you for preparing us for our unit on different kinds of communication. We are going to read about Helen Keller this week.

Thank you,

- Ms. Johnston's Class

- Southfield School, Class II

- Dear National Braille Press,

Thank you for inviting us. We enjoyed learning how blind people read. We also enjoyed learning and seeing how you make Braille. It was exciting to see how you made the bumps on the page. It must take a lot of patience to listen and check all of the braille. We will look for your books in the library.

Sincerely,

- Miss Lee's Class

- Southfield School

- Dear National Braille Press,

Thank you for the braille card with my name on it. I knew about braille before, but I didn't know quite so much about it. I learned that braille isn't only for blind people. It's for seeing people too, if you know how to read and understand it. I think you are doing a fine business so tell all of your friends to keep up the good work.

Sincerely,

- Southfield School

- Dear National Braille Press,

Thank you for taking us around your building. I loved it. Thank you also for letting us stomp on the metal sheets. I never knew that blind people aren't so different from other people. Also, I never knew that it took almost all those books to make only ONE dictionary! Thank you again.

Sincerely,

- Dexter School

Make a reservation for your group or class today!